+38 050 355 22 70

+38 050 355 22 70

+38 050 347 79 74

+38 098 591 40 79

+38 050 347 79 74

+38 098 591 40 79

Preparation of wood materials for the application of liquid wallpaper

Practical experience in the use of liquid wallpaper shows that quite often the surface that needs to be decorated turns out to be made of any types of wood-sheet materials. At the same time, it is well known that most of these materials are quite capricious, namely, they are sensitive to moisture. And so, let's understand all the features of working with wood-based panels, consider the typical mistakes, their consequences, and the correct methods for preparing such a surface.

Of course, if we are doing a global alteration of the interior, or we are carrying out finishing work from scratch, this is an ideal option. In this case, as a rule, there is a general work plan, and there is an idea of what decorative materials will be used, and accordingly, this plan takes into account what is more appropriate to use for surface preparation. However, more often than not, decorative work has a limited budget and does not include such global preparatory work.

Of course, if we are doing a global alteration of the interior, or we are carrying out finishing work from scratch, this is an ideal option. In this case, as a rule, there is a general work plan, and there is an idea of what decorative materials will be used, and accordingly, this plan takes into account what is more appropriate to use for surface preparation. However, more often than not, decorative work has a limited budget and does not include such global preparatory work.

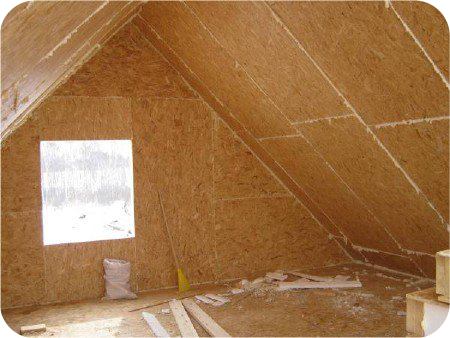

And now, let's imagine such an example. At the country house, on an attic floor high enough for residential use, the rafters are covered with sheets of either fiberboard, chipboard, or OSB, or even plywood. We are faced with the task of making the finishing. Obviously, it is difficult to find material better than liquid wallpaper for this task, place of application, temperature and humidity conditions.  But, if we apply them on the surface described above without proper preparation, then such an experiment will end with a wave-like curvature of wood-based panels, and, moreover, with the emergence of yellow spots. It's all the fault of the water that we add to the dry mixture, soaking the liquid wallpaper.

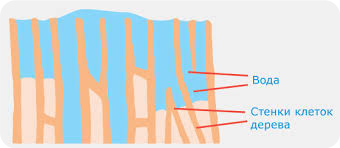

But, if we apply them on the surface described above without proper preparation, then such an experiment will end with a wave-like curvature of wood-based panels, and, moreover, with the emergence of yellow spots. It's all the fault of the water that we add to the dry mixture, soaking the liquid wallpaper.  It penetrates into the pores of wood, soaks, softens it, and pulls organic components, resins and glue from wood-based panels due to diffusion. It is these components that, if improperly prepared, appear on the surface in the form of yellow spots.

It penetrates into the pores of wood, soaks, softens it, and pulls organic components, resins and glue from wood-based panels due to diffusion. It is these components that, if improperly prepared, appear on the surface in the form of yellow spots.

We advise you to avoid the most common mistakes when preparing wood-based materials. None of the following methods has a moisture-proof effect. These include the following preparation methods:

The board is covered with water-based paint;

The board is covered with water-based paint;

The board is covered with gypsum or acrylic filler;

The board is covered with gypsum or acrylic filler;

The slab is covered with primer paint.

The slab is covered with primer paint.

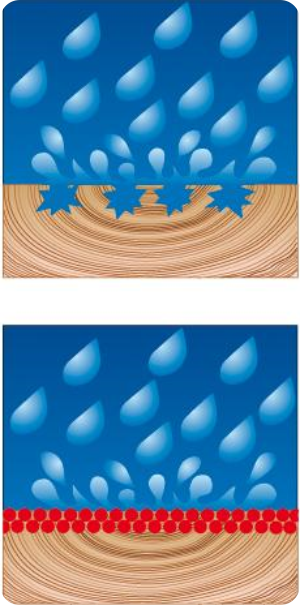

Proper surface preparation consists, first of all, in the fact that, firstly, we must create a layer on the surface of the wood board that will not let water through, excluding contact between water and the wood board. Secondly, we need to give this surface a solid light shade so that the base color would not be visible through on the light shades of liquid wallpaper. There are several ways to do this.

Method 1. The surface of any wood materials is opened with alkyd enamel, for example, PF-115, white. This enamel is used for painting and protecting against moisture both wood materials and steel structures. From the point of view of protection, this is an excellent solution. However, it must be borne in mind that during application, and about two days after application, alkyd enamel will emit a pungent odor, which must be actively ventilated. For this reason, this method is not always suitable for those premises where people are constantly during preparatory work.

Method 1. The surface of any wood materials is opened with alkyd enamel, for example, PF-115, white. This enamel is used for painting and protecting against moisture both wood materials and steel structures. From the point of view of protection, this is an excellent solution. However, it must be borne in mind that during application, and about two days after application, alkyd enamel will emit a pungent odor, which must be actively ventilated. For this reason, this method is not always suitable for those premises where people are constantly during preparatory work.

Method 2. To create a moisture insulating layer, you can use any, in your opinion, proven moisture insulators compatible with wood materials. However, we recommend using the BIOPLAST brand AQUABLOCK impregnation primer. It is sold as a 1:10 concentrate and has two uses. First application: if we dilute the AQUABLOCK impregnating primer with water in a ratio of 1:10, we will get an ordinary acrylic primer, suitable for the preparation of standard surfaces. However, in the case of preparing wood-based panels, we use only its second application: the primer-impregnation AQUABLOC is applied to the surface undiluted. At the same time, it is practically odorless, rather viscous, and after drying it has excellent moisture-insulating characteristics. When applied undiluted, it creates a colorless film on the surface of wood materials, which water can no longer penetrate. Drying time: about 3 hours.

Method 2. To create a moisture insulating layer, you can use any, in your opinion, proven moisture insulators compatible with wood materials. However, we recommend using the BIOPLAST brand AQUABLOCK impregnation primer. It is sold as a 1:10 concentrate and has two uses. First application: if we dilute the AQUABLOCK impregnating primer with water in a ratio of 1:10, we will get an ordinary acrylic primer, suitable for the preparation of standard surfaces. However, in the case of preparing wood-based panels, we use only its second application: the primer-impregnation AQUABLOC is applied to the surface undiluted. At the same time, it is practically odorless, rather viscous, and after drying it has excellent moisture-insulating characteristics. When applied undiluted, it creates a colorless film on the surface of wood materials, which water can no longer penetrate. Drying time: about 3 hours.

And only after that, to give an even color to the surface, it can be painted with white water-based paint or primer paint with quartz filler of the BIOPLAST trademark. It makes the surface white, primed and rough. However, it is not a moisture insulator in itself, and the use of AQUABLOCK impregnation primer before applying the primer paint is mandatory for the correct preparation of wood-based panels. Drying time: 4 hours.

And only after that, to give an even color to the surface, it can be painted with white water-based paint or primer paint with quartz filler of the BIOPLAST trademark. It makes the surface white, primed and rough. However, it is not a moisture insulator in itself, and the use of AQUABLOCK impregnation primer before applying the primer paint is mandatory for the correct preparation of wood-based panels. Drying time: 4 hours.

Regardless of whether we used the first or second preparation method - our surface is ready for applying liquid wallpaper. Successful and easy decorative work with BIOPLAST liquid wallpaper!